Job Costing and Machine Utilisation (Back)

The ‘Holy Grail’ - what most companies require but rarely achieve.

Most companies are aware of whether they made a Profit or Loss for any particular month but often do not know how profitable individual Jobs were or how profitable individual Customers are compared one with another.

Often companies Quote work and monitor Income on a global Rate per Hour achieved per Man Hour - but this must be recognised as a potentially dangerous practice where an unskilled Labourer with a file doing some Bench work is valued on the same basis as a sophisticated CNC machine costing £100,000 being run by a very skilled Machinist.

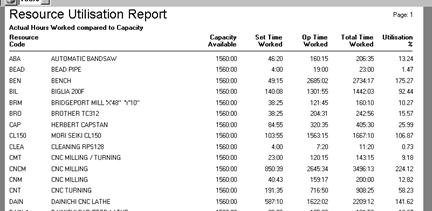

1st Manufacturing enables a variety of easy to capture information to be organised automatically into a variety of analysies that will shed much light on the detail both by Job, Part, Customer and Resource.

Information can be captured in a variety of ways:

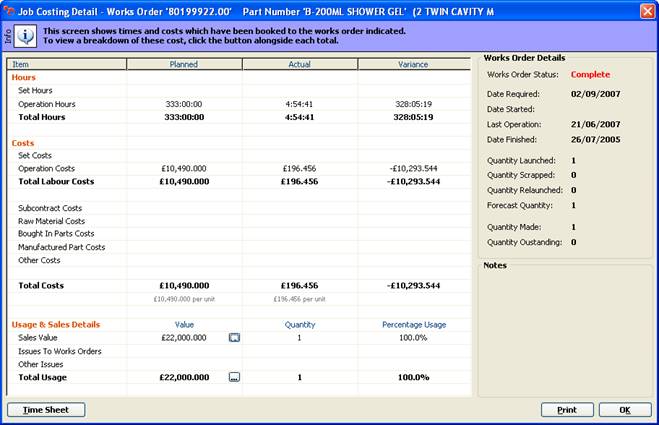

- Time - at its simplest - by capturing the Employee Time Bookings from details recorded on the Route Card and processed at the end of a Job ( along with Direct Costs of Materials, Parts and Sub-Contract )

- or via Time Bookings recorded on Daily Employee Timesheets processed daily and providing a more up-todate view on the progress of Jobs

- or via Shop Floor Data Capture terminals capturing the Time information automatically ‘real-time’ as Operators move from one task to another. This option combines the benefits of a conventional Time Clock for Payroll with Shop Floor Data Capture of Job Times and Progress. Specialised ‘Touch Screen’ Monitors combined with Laser Scanners make this a very slick and easy to use system

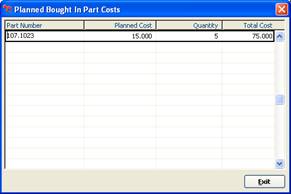

- Purchase Costs (for Material, Bought-In Parts or Sub-Contract) can be collected via the Purchasing module or just via simple Cost Data entry.

- Stock Costs (for Raw Material or Stock Items) can be similarly collected via our Stock Control module or just via simple Cost Data entry.

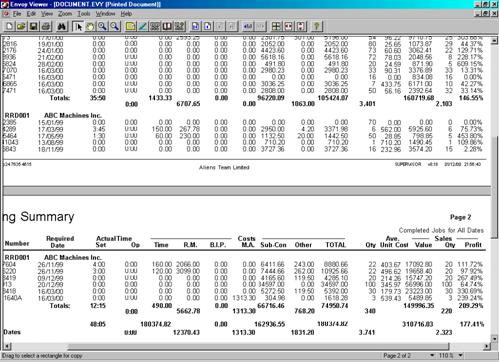

Job Costing Enquiries and Reports can then produced by Job, Part Number (showing ‘Batch Cost to Make’ History), Customer and Accounting Month.

Job Costing and Time comparisons between original Quotation, Manufacturing Instruction Plan and Actuals are also available.